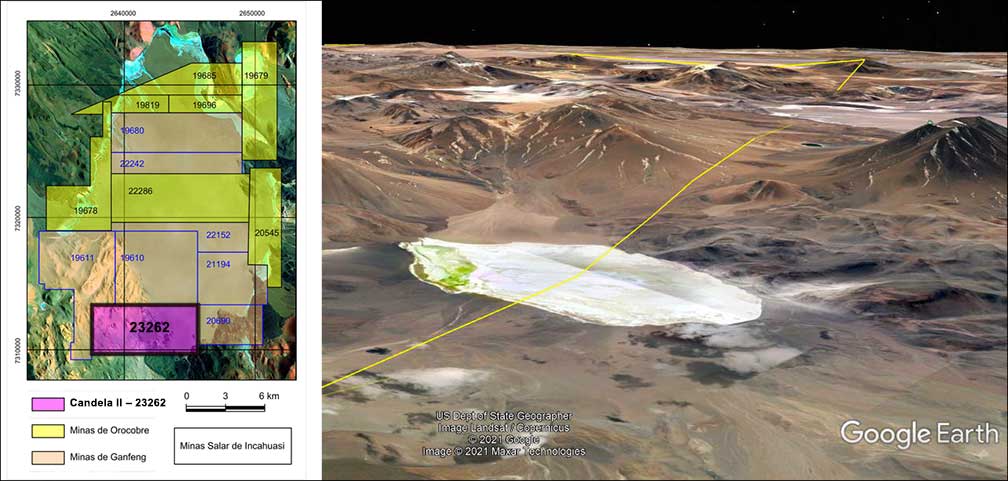

Candela II Project, Incahuasi Salar, Lithium Triangle Argentina

AIS Resources currently has a 20% interest in a mining licence in the highly prospective Incahuasi Salar located in Argentina’s world-renown Lithium Triangle. The Candela II licence covering 3 sq km, neighbours a project owned by Gangfeng Lithium, China’s largest producer of the battery metal and Orocobre (ASX:ORE), a lithium producer in Argentina.

Our partner in the Candela II Project is Spey Resources Corporation (CSE: SPEY), a public company, that has optioned the Exploration license for 12 months to complete due diligence and further exploration work. Tech One has the right to acquire 100% of the property for US$1,000,000 (CAD1.3 million). The option fee paid by Tech One was US$100,000 and a further fee of US$100,000 payable by Tech One in six months time.

Aerial view of the Salar Candela II Project and the Incahuasi Salar located in the Lithium Triangle in Argentina.

AIS Resources – Operator and Exploration Team

Tech One appointed and contracted AIS to be the operator and exploration team for the Incahuasi Salar Candela II Project – with the one-year exploration plan outlined by AIS’s technical team. Upon a successful resource outcome, Tech One has the option to acquire AIS’ 20% stake by paying US$6,000,000. This is based upon establishing a resource estimate of at least 45,000 tonnes of lithium metal equivalent. The fee increases by US$250,000 for each increment of an additional 5 tonnes. Previous explorers have sampled brines between 270-300 ppm from the top 50 metres of the Incahuasi Salar Candela II Project.

L: Concession Map of the main land holders neighbouring Salar Candela II. R: Google Earth view of the Incahuasi Salar where previous explorers have sampled brines between 270-300ppm, from the top 50 metres of the Salar.

![[Most Recent Quotes from www.kitco.com]](https://www.kitconet.com/charts/metals/gold/tny_au_en_usoz_2.gif)